Guangdong WauTech Co., Ltd. was established in August 2015, located in Xiegang, Dongguan, adjacent to Shenzhen with very convenient transportation. We are a modern production enterprise specializing in metal product processing.

Company Scale and StrengthThe company covers an area of 7,500 square meters with modern production workshops and advanced production and testing equipment. The proportion of professional technicians is high, ensuring product quality and production efficiency through exquisite skills. The company specializes in stainless steel insulated cups and various metal product processing, strictly controlling from material selection to packaging, and can customize products of different specifications and styles according to customer requirements.

The company has a professional mold design and manufacturing team, equipped with advanced equipment such as CNC machine tools, milling machines, drilling machines, punching machines, and hydraulic presses, capable of designing and manufacturing high-precision, complex structure mold processing while focusing on mold optimization and improvement; the production workshop has a reasonable layout and advanced equipment, including laser welders, argon arc welders, brazing machines, spot welders, polishing machines, hydroforming machines, vacuum furnaces and other machine equipment, featuring high precision and high efficiency, while introducing advanced production management systems to achieve full-process monitoring. To ensure product quality and precision, the company has established a specialized measurement workshop equipped with a series of advanced measuring equipment such as coordinate measuring machines, optical comparators, salt spray testers, and various measuring instruments. Precise measurements and inspections are conducted on product dimensions, shapes, and positions to ensure products meet customer requirements and relevant standards.

Quality and MarketThe company always adheres to the philosophy of "quality first, customer supreme," establishing a complete quality management system and strictly operating according to ISO9001 quality standards with multiple quality inspection checkpoints. With excellent quality and good service, our products sell well both domestically and internationally, and we have established long-term cooperative relationships with many well-known enterprises.

Future ProspectsLooking ahead, the company will uphold the corporate spirit of "integrity, innovation, and win-win," continuously increase technological research and equipment investment, improve product quality and competitiveness, and strive to become a globally leading metal processing enterprise, providing customers with better products and services and promoting industry development.

Whether it's a small step or a big step, it should drive progress

Developing employees, achieving customers, and giving back to society

Win win cooperation, pragmatic innovation

Integrity, pragmatism, dedication, and innovation

Committed to becoming a leading global hardware processing enterprise, providing customers with higher quality products and services, and promoting industry development

We are possessing modern production workshops with complete production equipment and professional testing equipment

CNC lathes

CNC lathes

Lathes

Lathes

Turret milling machines

Turret milling machines

Hydroforming machines

Hydroforming machines

Stretching (deep-draw) machines

Stretching (deep-draw) machines

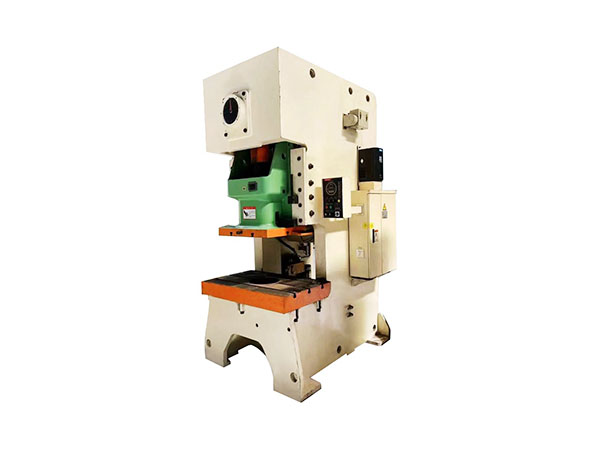

Punching machines

Punching machines

Tube drawing machines

Tube drawing machines

Vacuum furnaces

Vacuum furnaces

Brazing machines

Brazing machines

Heat shrink machines

Heat shrink machines

Laser welding machines

Laser welding machines

Laser welding machines

Laser welding machines

Laser cutting machines

Laser cutting machines

Laser cutting machines

Laser cutting machines

Thread rolling machines

Thread rolling machines

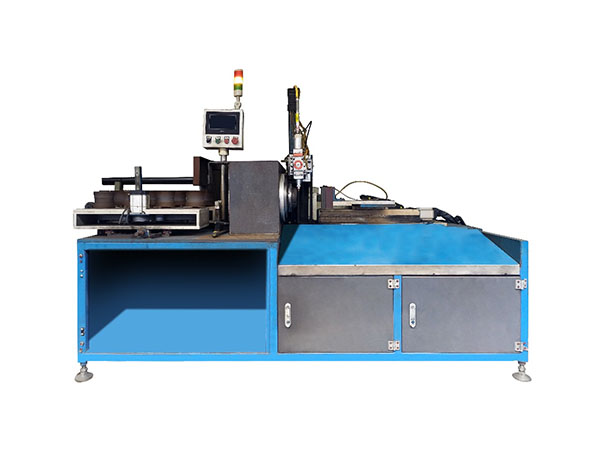

CNC welding machines

CNC welding machines

CNC hydraulic necking machines

CNC hydraulic necking machines

CNC flanging machines

CNC flanging machines

Strict control from material selection to packaging, able to customize products of different specifications and styles according to customer requirements

Communication of RequirementsUnderstanding customers' specific functional requirements for insulated cups

Providing SamplesSupporting customization based on provided drawings or molds, offering multiple solution options

Contract SigningSigning formal contracts after price confirmation

Production ProcessingPerforming manufacturing processes such as stamping, welding, and polishing

Quality InspectionConducting insulation and sealing tests to ensure product quality

On-time DeliveryPackaging products properly to ensure no damage during transportation